About Us

History

We Are Located In Vijayawada Part Of Andhra Pradesh

OUR VISION

To become a Global Player in Delivering World Class Quality Products fulfilling Global and Domestic Customer Requirements

OUR MISSION

To become the most Preferred Supplier to our Customers in next 3 years through Continual Customer Engagement and Employee Involvement.

CORE VALUES

- Motivating our people

- Customer centric culture

- Harnessing superior technologies

- Strong Partnerships

- Sensitivity to Ecosystem

Our Team

R Balakrishnan

Group Advisor

R Balakrishnan

Group Advisor

M Krishna

Director

M Krishna

Director

V Balaji

CEO

V Balaji

CEO

Pratul Bansal

Head : Operations

Pratul Bansal

Head : Operations

Design

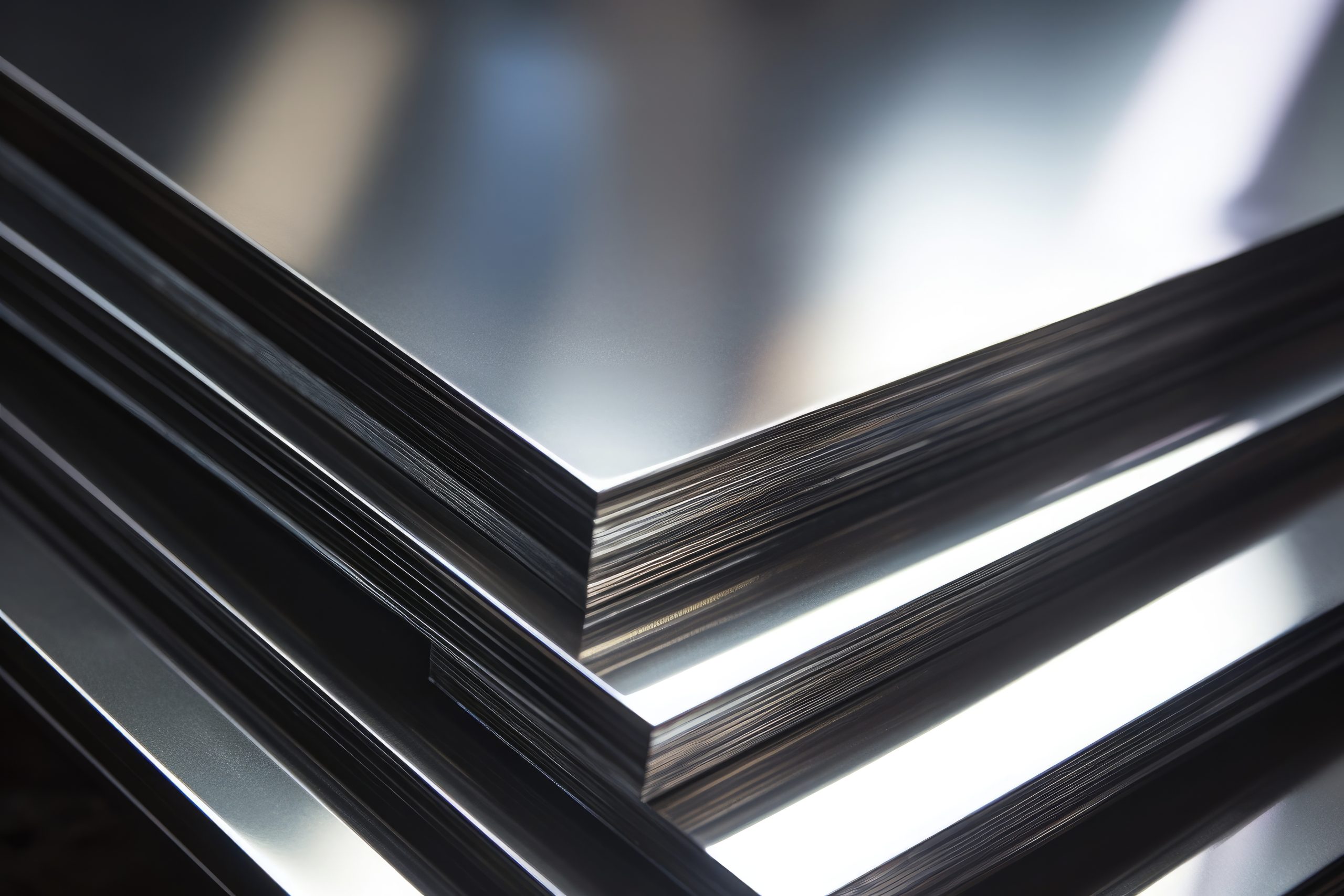

Raw materials we process

For our different range of products, we use various grades of steels

- RAMOR500, RAMOR550,

- ARMOX500

- E250, E350, E450 EN grade Structural Steels

- Weldox S690QL, S700

- Hardox HB400®, HB450®, HB 500®

- Bars : EN8D, EN16T & other alloy steels

- Imported High grade Casted GETs

Advanced Welding Expertise

All our Welders are certified to ISO 9606-1 135 P BW FM1 S t16 PA ss, nb, ml as per ISO 15609-1:2019 Welding Procedure Specifications.

We follow and adhere highest international quality standards and inspections are done as per Customer Specifications.

infrastructure

Our Manufacturing is spread over an area of 15 Acres with Covered area of 1.5 Lac Sq.Ft. out of which 50K Sq.Ft. is an independent Paint Shop.

Our facility is equipped to handle components / products weighing upto 15 MT and we have large working space on the shop floor to accommodate heavy & big products.

Our World Class Paint Shop consists of large Shot Blasting Chamber, conveyor type Paint Booth through which we deliver automotive grade paint quality.